- Innovative breakthrough of large metal polishing machine: magnetic polishing

- Magnetic polisher and plane polisher: Gemini of precision manufacturing

- Why magnetic polishers process metal surfaces so quickly

- Guan Gu magnetic polishing machine removes high-temperature oxidation color of metal

- Magnetic polishing machine actual measurement: aluminum radiator polishing and deburring effect is significant

- Magnetic polishing machine: a tool beyond metal surface treatment

E-mail:zhihong@szguangu.com

Phone:18626103335

TEL:400-800-3945

Address:No. 333, Zixu Road, Xukou Town, Wuzhong District, Suzhou

Causes and solutions of burr in stamping parts

Stamping burr is produced in the process of blanking or stamping, usually due to the following reasons:

1. Die wear: When the die is used for too long or too frequently, it will be worn and deformed, resulting in uneven edges of stamping parts and burrs.

2. The hardness of the material is too high: if the hardness of the stamping material is too high, there will be intractable burrs in the stamping process.

3. Inappropriate cutting angle: If the cutting angle of the punch is inappropriate, the edge of the punched parts may be rough, resulting in burrs.

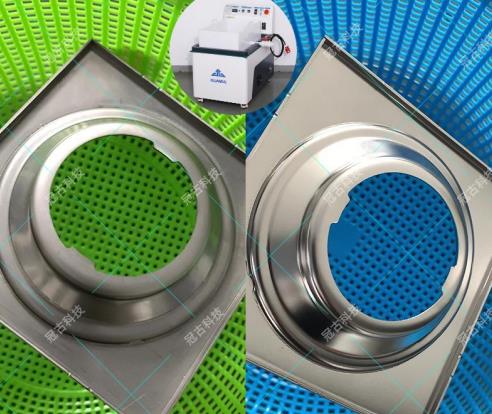

Deburring of stamping parts, free samples by magnetic polishing machine

4. Insufficient lubrication: If there is insufficient lubrication, the friction will increase, which may lead to uneven stretching of the material, resulting in burrs.

5. Improper adjustment of punch or die: If the punch or die is not adjusted correctly, it may also lead to uneven edges of stamping parts and burr.

In view of the above reasons, corresponding measures can be taken to avoid or reduce the occurrence of stamping burrs, such as replacing worn dies in time, using materials with appropriate hardness, adjusting cutting angle, and strengthening lubrication.

Aiming at the burr problem of stamping parts, the following removal schemes can be adopted:

1. Manual deburring: By manually using grinding tools, such as sandpaper, Grinder, etc., the edges of stamping parts are polished and trimmed to achieve a flat effect.

2. Chemical deburring: the surface of stamping parts is treated with chemical corrosive liquid, so that burrs can be filed and smoothed.

3. machine deburring: It is more efficient to deburr stamping parts by using punch automation equipment or other special deburring machines, but it requires a certain investment cost.

4. Mold optimization: By optimizing the mold, improving the structure of the cutting opening and adjusting the gap of the mold, the burr phenomenon in the stamping process is avoided as much as possible, and the deburring process is reduced in the production process.

5. Lubrication improvement: properly strengthen lubrication measures, reduce the deformation and hardening of stamping components under the action of friction force, help materials stretch evenly, and thus reduce burr generation.

It is necessary to choose a suitable deburring scheme according to the specific situation in order to optimize the production efficiency and product quality.

-

2022-10-18Deburring of stainless steel stampings